Pressure Switch

Product Details:

- Mounting Type Panel Mount

- Power Source Electric

- Sealing Type IP65 Rated

- Features Corrosion Resistant, Compact Design, Precise Switching

- Accessories Mounting Bracket, Cable Gland

- Efficiency High Switching Accuracy

- Operating Pressure 0.5 to 10 bar

- Click to View more

Pressure Switch Price And Quantity

- 4500.00 - 4500.00 INR/Piece

- 4500 INR/Piece

- 1 Piece

Pressure Switch Product Specifications

- 220V AC

- Panel Mount

- Pressure Switch

- Adjustable Set Point

- Industrial Automation, Hydraulic Systems, Pneumatic Controls

- Instant Response

- 0.5 to 10 bar

- Mounting Bracket, Cable Gland

- High Switching Accuracy

- Stainless Steel

- IP65 Rated

- Corrosion Resistant, Compact Design, Precise Switching

- Electric

- Single Pole Double Throw (SPDT)

Pressure Switch Trade Information

- Jaipur

- Cash on Delivery (COD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 3-4 Piece Per Day

- 1-2 Days

- Yes

- Contact us for information regarding our sample policy

- Standard

- Rajasthan

- ISO , GST

Product Description

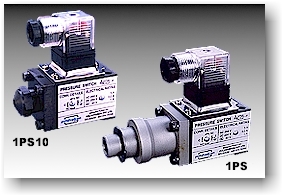

Pressure Switch

POLYHYDRON PRESSURE SWITCH 1PS350

Description

Non adjustable differential type. Spring loaded sealed piston construction. Encapsulated design for protection against dust. Six pressure ranges available, which can be adjustable upto 10, 50, 100, 200, 350 and 420 bar.

Technical Specifications

Construction .................................. Spring loaded sealed piston type.

Mounting style ............................... Subplate mounting.

Interface ........................................ Factory standard.

Mounting position ........................... Optional. (Pr. sensing port facing downward preferred)

Hydraulic medium ........................... Mineral oil.

Viscosity range .............................. 10 cSt to 380 cSt.

Fluid temperature range ................. -20 oC to +70 oC.

Oil cleanliness requirement ............ As per ISO 16/13.

Maximum Operating Pressure ......... Refer pressure setting table

Pressure ranges available .............. Adjustable up to 10, 50, 100, 200, 350 and 420 bar.

Switching pressure differential ........ Refer graph.

Switching frequency ....................... 120 / min.

Switching accuracy ........................ < + 1 %

Life .............................................. 1 million cycles min.

Electrical rating .............................. 250 VAC 5.0 A

50 VAC 1.0 A 250 VDC 0.2 A

Robust and Reliable Performance

Designed for tough industrial environments, this pressure switch delivers consistent performance over a wide operating pressure range of 0.5 to 10 bar. With low hysteresis under 1% and rapid switching, it brings exceptional accuracy and responsiveness to your automation, hydraulic, or pneumatic systems.

Safety and Durability Assured

A stainless steel body and IP65 ingress protection offer resilience against corrosion, dust, and water, making this switch suitable for heavy-duty or demanding settings. The product is engineered to ensure safe operation in high humidity (up to 95% RH) and harsh industrial conditions.

Convenient Installation and Adjustment

With its compact form factor, panel mounting capability, and supplied accessories such as a mounting bracket and cable gland, this switch is straightforward to install. The manual knob allows precise set point adjustments, tailoring response to your systems needs.

FAQs of Pressure Switch:

Q: How do I adjust the set point on this pressure switch?

A: The set point can be adjusted manually using the control knob located on the switch body. Simply rotate the knob until the desired pressure value is reached, according to your application requirements.Q: What applications is this pressure switch best suited for?

A: It is ideal for industrial automation, hydraulic systems, and pneumatic controls, where precise and reliable pressure monitoring and switching are required. The corrosion-resistant stainless steel body ensures suitability for harsh environments.Q: When should I consider replacing the pressure switch?

A: With a minimum operational life of 1 million cycles, the switch is built for longevity. Replacement may be considered after extensive use or if you notice inaccurate switching, response delays, or visible damage from severe external impact.Q: Where can the pressure switch be mounted?

A: The device is designed for panel mounting, making it adaptable to most industrial setups. It comes with a G1/4" BSP pressure port thread, ensuring compatibility with standard pressure lines.Q: What is the process for installing the pressure switch?

A: Installation involves securing the unit using the provided mounting bracket, connecting the cables through the cable gland, and threading the pressure port to your system. Ensure all connections are secure for optimal IP65-rated sealing.Q: How does the ingress protection (IP65) rating benefit my system?

A: The IP65 rating safeguards the switch against ingress of dust and low-pressure water jets, extending device life and ensuring reliable operation in both indoor and outdoor industrial environments. This protection is crucial for systems exposed to dust or moisture.Q: What are the key benefits of using this pressure switch in my application?

A: Key benefits include precise switching with low hysteresis, rapid response times, compact and durable construction, long operational life, and resistance to corrosion and environmental ingress, all contributing to minimal maintenance and maximum uptime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free